For the Planet

Each of our bag has a story to tell. A story on how it is made, what materials have been used for it, who has made it and how the price of the bag is built up. When purchasing a bag, we want you to make a conscious choice. Therefore we are giving our customers as much information as possible about the products.

Circular design & Round 2

We have a great respect for the materials we use. Our designs are crafted to minimize the cutting leftovers. The larger ones are used for creating smaller purses, wristbands and keychains etc. So far we have managed to reduce the leftovers to only 2-4%. Our goal is to reach zero waste in the next few years.

The bag designs follow our own circular design concept that we call Round 2. It enables us to give the product and the material the longest lifetime. This is why the design is minimal and with no decor – all details have function. As high quality natural finish leather is used then the decor part is done by the material itself – in time it will have great patina and it tells its story.

Changeable parts enable simple maintenance and after-care. Face-lift of used products is made easy and allows us to direct refreshed bags into the next rounds of usage. The big material surface without any seams also allows some redesigning if necessary (e.g. if stains and scratches occur it’s possible to add a pocket etc) or create something completely new out of the used material.

If your bag ever gets spoiled with stains that won’t come off or if its function has no use to you anymore, return it to us, and we will give it a new life. In return you will get store credit depending on the condition of the bag.

If your bag ever gets spoiled with stains that won’t come off or if its function has no use to you anymore, return it to us, and we will give it a new life. In return you will get store credit depending on the condition of the bag.

Why leather?

We use vegetable tanned leather from Europe – e.g. tanneries like Tärnsjö Garveri from Sweden, Sørensen Leather from Denmark, tanneries from Italian Vegetable Tanned Leather Consortium and Splenda Tannery from Spain. For some occasions we also order chrome tanned leather from Palomares tannery from Spain. Usually we avoid using chrome tanned leather but sometimes it can be more suitable for some special projects.

Vegetable tanned leather is made by using natural tanning agents and no harmful chemicals are used. It develops a delightful patina over time and ages beautifully. It is durable, easy to care for and it lasts decades and even lifetimes. Leather biodegrades but our first and utmost aim is to keep it in the circle as long as possible.

Vegetable tanned leather is very durable. To keep it good-looking it is recommended to moisturize it with special leather cream every couple of months. However it does not need regular washing which significantly reduces the water and energy use compared to some alternative materials.

Vegetable tanned leather does not come without problems. It has many issues in the beginning of its lifecycle – land exploitation and methane emissions from growing cattle, animal rights, high water and energy use. There are also negative effects on the environment during the tanning process. On the positive side – upgrading raw hides into a high quality leather has much less environmental impact compared to burying or burning them and it is still the longest lasting material for bags.

We are constantly keeping ourselves updated with non-animal alternative materials suitable for bags. So far, unfortunately we have not found one that would not have big environmental problems of their own. Some contain plastic, some are still not available in mass scale, some need to be transported to us from other side of the world and so far we have not found one to last as long as vegetable tanned leather.

We are constantly keeping ourselves updated with non-animal alternative materials suitable for bags. So far, unfortunately we have not found one that would not have big environmental problems of their own. Some contain plastic, some are still not available in mass scale, some need to be transported to us from other side of the world and so far we have not found one to last as long as vegetable tanned leather.

Care & Repair

In general, a vegetable tanned leather bag needs minimal care during its lifetime. You can do it yourself by following simple instructions or bring it to us and we do it for you – we will clean it, moisturize it, replace the worn-out parts and pamper the overall look as well.

The handles, pockets and other details of the bag can be easily refreshed or changed when they have worn out or the user would like something different in function or decor.

Local manufacturing

Most bags are made in our studio in Tallinn, Estonia. All these bags are marked with the names of the artisans who made it. Once you receive the bag, look inside it to discover who has made it. In addition to our crafters, occasionally a small family owned local manufacturer Kolm in Tartu (located also in Estonia) helps us out. They have a long experience with leather work. We are in frequent contact and the bags that are made by them follow the same technical specifications, quality and care as is our studio.

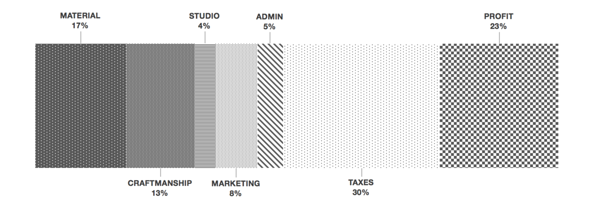

Transparent pricing

A handmade leather bag is an investment that will serve you for decades and even lifetimes. When buying a bag you should know why it costs what it costs. To illustrate this, we are disclosing full information on this. This breakdown is made as an average of the bags that are in Stella Soomlais’ collection.

Rental service & second hand

There is no need to own all different kinds of bags. We rent our bags for short-term – for a weekend, to try and get the feel of the bag or to go on a holiday. This is also a great way to try out and get the feeling of the bag before buying it. We will deduct the rental price from the bag price if you decide to buy or order the same model.

Instead of buying a new bag you can also buy a used one from our second-hand corner in the studio shop.

Awards

2020 Estonian Responsible Business Index Gold level

2020 Estonian Responsible Entrepreneurship Forum, special award for social entrepreneurship

2019 Estonian Responsible Business Index Silver level

2018 Estonian Responsible Business Index Bronze Level